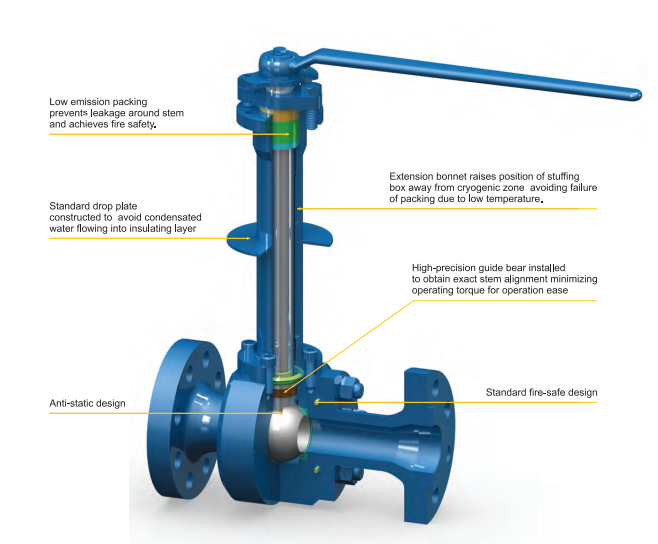

QL Cryogenic ball valve design feature

The cryogenic ball valves has the special design structures meet to such service safety use.| Main Parts Material | ||||

| BODY | LCB/LF2 | LC3/LF3 | CF8/F304 | CF8M/F316 |

| BALL | F304 | F304 | F304 | F316 |

| STEM | F304 | F304 | F304 | F316/XM-19 |

| SEAT | PCTFE/RPTFE/PEEK | |||

| PACKING | PTFE/ GRAPHITE | |||

| BOLTING | A193 L7/A194 4 | A193 B8/A194 8 | A193 B8M/A194 8M | |

Since cryogenic ball valves are used in low temperature conditions, the valve must be fully dried before delivery. The test medium in factory usually is be helium gas.If there is any liquid in valve body, the liquid will risk freeze at low temperature and will generate pressure on the internal components of the valve. The pressure will damage the valve sealing and pipeline damage risk. It’s also the reason why the cryogenic ball valve valve is replaced by the air pressure test instead of hydraulic test on site test. The construction site test facility is quite limited and the valve need be strictly dried before use.QL Cryogenic ball valves designated in highest performance and produced in strictest quality, can meet the highest standard cryogenic service,and wildly applied for safety transportation for processing,storage,shipment and distribution of ethylene,Liquid Nitrogen, Oxygen, LPG, Liquefied Natural Gas (LNG) and other low temperature liquefied gases. As an efficient and storable clean energy, LNG has shown broad development prospects in all aspects of the industrial chain. Cryogenic ball valve is most demanding valve in the cryogenic liquid storage and transportation equipment system. It has the advantages of flexible switching, reliable sealing, safety and stability etc.The valve parts for cryogenic service need do the cryogenic treatment to make sure the valve material performance will suitable for low temperature. The cryogenic treatment is the process of putting valve parts to low temperatures by medium nitrogen -196 ℃ in order to remove residual stresses and improve wear resistance in steels. QILONG cryogenic treatment for ball valve part and cryogenic test for finished valve .

Since cryogenic ball valves are used in low temperature conditions, the valve must be fully dried before delivery. The test medium in factory usually is be helium gas.If there is any liquid in valve body, the liquid will risk freeze at low temperature and will generate pressure on the internal components of the valve. The pressure will damage the valve sealing and pipeline damage risk. It’s also the reason why the cryogenic ball valve valve is replaced by the air pressure test instead of hydraulic test on site test. The construction site test facility is quite limited and the valve need be strictly dried before use.QL Cryogenic ball valves designated in highest performance and produced in strictest quality, can meet the highest standard cryogenic service,and wildly applied for safety transportation for processing,storage,shipment and distribution of ethylene,Liquid Nitrogen, Oxygen, LPG, Liquefied Natural Gas (LNG) and other low temperature liquefied gases. As an efficient and storable clean energy, LNG has shown broad development prospects in all aspects of the industrial chain. Cryogenic ball valve is most demanding valve in the cryogenic liquid storage and transportation equipment system. It has the advantages of flexible switching, reliable sealing, safety and stability etc.The valve parts for cryogenic service need do the cryogenic treatment to make sure the valve material performance will suitable for low temperature. The cryogenic treatment is the process of putting valve parts to low temperatures by medium nitrogen -196 ℃ in order to remove residual stresses and improve wear resistance in steels. QILONG cryogenic treatment for ball valve part and cryogenic test for finished valve .